Contact number

Contact number

1. Main Functional Features

1. Mitsubishi PLc control system of Japan, suitable for the production of sand mold or sand mold by fast curing of cold box resin sand with triethylamine.

2. It is equipped with high-performance SL series triethylamine generator to blow ammonia in one time with high efficiency.

3. Core jacking device ensures that the sand core is left in the bottom mold after opening, and the bottom mold is automatically jacked out after moving out, without the need to connect the mold car.

4. Equipped with hydraulic pump station system, mold closing and mold opening hydraulic drive.

5. Linear guide rail is adopted for precise guidance and positioning

6. Automatic lubrication oil supply system is adopted to ensure equipment accuracy and extend service life.

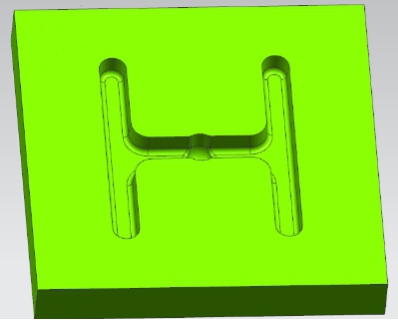

2. Reference design of Mold Layout

Top Part |  Bottom Part |

|

Jobs after casting (pink runner/gating) |

3. Molding process flow diagram

|

Figure: Process Flow Diagram (reference only) |

4. Reference picture

Automatic Sand Mold & Core Making Machine (main machine with control cabinet) |

Overall machine with sand storage, automatic sand loading bucket, sand mixer, and operation platform. |

5. Main Technical Specification

Item | Technical data |

Max. core box size (LxWxH)(mm) | 1000×800×600mm |

Capacity (Mold/ hour) | 70-120 |

Open/close mold distance(mm) | 420-920 |

Maximum clamping mold force(KG) | 15000 |

Maximum top output(KG) | 3000 |

Drive way | Hydraulic+ pneumatic |

Control system | PLC with HMI (Monitor) |

Main Machine Dimension L x W x H(mm) | Main Machine: 4110×1700×3590

|

Overall Machine Height (mm) | 8363mm (above ground) + 800mm (underground) |

Machine Weight(KG) | 6500 |

上一篇:None

下一篇:None